Industrie Bildung: Schlüsselkomponenten und Struktur eines Industrie-Glasofens

Der Industrie-Glasofen ist eine hochtechnisierte Struktur, die aus mehreren miteinander verbundenen Abschnitten besteht, die jeweils darauf ausgelegt sind, effizientes Schmelzen und Läutern von Glas zu gewährleisten. Das Verständnis dieser Komponenten hilft Herstellern, die Ofenleistung zu optimieren und die Betriebsdauer zu verlängern.

Der Ofen ist typischerweise in vier Hauptzonen unterteilt: den Schmelztank, das Läuterzone, das Arbeitsende und das Zuführsystem. Der Schmelztank ist der Ort, an dem die Rohmaterialien zuerst eintreten und unter Temperaturen von über 1.500 °C zu schmelzen beginnen. Diese Zone verwendet leistungsstarke Brenner oder elektrische Systeme, um ein schnelles Schmelzen zu erreichen.

Die Läuterzone konzentriert sich auf die Entfernung von Blasen und die Homogenisierung des geschmolzenen Glases. Eine ordnungsgemäße Läuterung stellt sicher, dass das Endprodukt eine hohe Transparenz und strukturelle Integrität aufweist. Diese Phase kann spezielle Blasensysteme oder Rührwerke umfassen, um den Läuterprozess zu beschleunigen.

Als Nächstes kommt das Arbeitsende, wo das geschmolzene Glas auf eine geeignete Formgebungstemperatur leicht abkühlt. Kontrolliertes Abkühlen verhindert Defekte und gewährleistet einen stabilen Fluss während der Formgebung. Eine präzise Temperaturführung ist entscheidend für die Herstellung von Flachglas, Flaschen oder Präzisionsoptikglas.

Eine weitere wichtige Komponente ist die feuerfeste Auskleidung, die die Ofenstruktur vor chemischer Korrosion und extremer Hitze schützt. Hochwertige feuerfeste Materialien verbessern die Haltbarkeit des Ofens und reduzieren die Wartungskosten.

Der Industrie-Glasofen umfasst auch energiesparende Technologien wie Regeneratoren, Rekuperatoren und Wärmetauscher. Diese Systeme gewinnen die verlorene Wärme aus den Abgasen zurück und verbessern den Gesamtwirkungsgrad der Verbrennung.

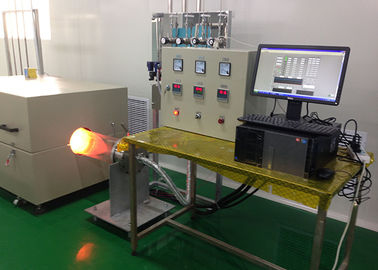

Moderne Öfen integrieren digitale Steuerungen, Gasflussüberwachung, automatische Zuführsysteme und Echtzeit-Temperatureinstellungen. Diese Funktionen ermöglichen es Fabriken, die Ofenbedingungen zu verfolgen und die Schmelzprozesse kontinuierlich zu optimieren.

Zu den Industrien, die sich auf diese Systeme verlassen, gehören Floatglaswerke, Pharma-Glashersteller, Behälterabfüllfabriken und Spezialglashersteller. Mit der wachsenden Nachfrage nach Hochleistungsmaterialien steigt auch der Bedarf an einer stabilen und zuverlässigen Ofeninfrastruktur weiter an.

Zusammenfassend lässt sich sagen, dass der Industrie-Glasofen eine komplexe und wesentliche Komponente des Glasherstellungsprozesses ist. Sein strukturelles Design und seine intelligenten Funktionen gewährleisten eine gleichbleibende Schmelzqualität, eine hohe Produktionseffizienz und eine langfristige Betriebszuverlässigkeit.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!