Industrielles Fachwissen: Wie ein industrieller Glasofen die Schmelzeffizienz verbessert

Das Schmelzen ist die energieintensivste Phase in der Glasproduktion und macht den Industrielle Glasofen zum Schlüsselfaktor für die Bestimmung der Produktqualität und der Wirtschaftlichkeit der Anlage. Dieser Artikel untersucht, wie die Ofentechnologie die Schmelzeffizienz verbessert und die moderne Fertigung unterstützt.

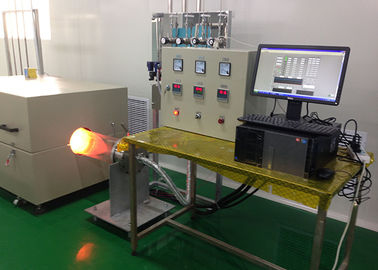

Der industrielle Glasofen arbeitet nach dem Prinzip der Hochtemperaturfusion. Rohstoffe werden kontinuierlich in den Ofen eingespeist, wo leistungsstarke Brenner eine kontrollierte thermische Umgebung erzeugen. Fortschrittliche Öfen verwenden Sauerstoff-Brennstoff-Verbrennung oder elektrische Zusatzsysteme, um eine schnelle Erwärmung mit minimalem Energieverlust zu erreichen.

Eine der wichtigsten Technologien zur Verbesserung der Effizienz ist die regenerative Beheizung. Bei diesem System strömen heiße Abgase durch Checker-Steine, um Wärme zu speichern. Die gespeicherte Wärme wird dann an die einströmende Verbrennungsluft zurückgeführt, wodurch der Brennstoffverbrauch um bis zu 35 % reduziert wird. Dies macht regenerative Öfen zur bevorzugten Wahl für die Herstellung von Floatglas und Behälterglas.

Rekuperative Öfen hingegen verwenden Wärmetauscher, um Wärme aus den Abgasen zurückzugewinnen. Obwohl sie einfacher aufgebaut sind, tragen sie ebenfalls zu erheblichen Energieeinsparungen und einer stabilen Ofenleistung bei.

Die Temperaturhomogenität ist für das richtige Schmelzen unerlässlich. Moderne industrielle Glasöfen integrieren Lasermesssysteme, Infrarotkameras und digitale Steuerungssoftware. Diese Werkzeuge gewährleisten eine gleichmäßige Temperaturverteilung, wodurch die Schmelzzeit verkürzt und die Glashomogenität verbessert wird.

Ein weiterer technologischer Fortschritt ist das elektrische Zusatzsystem. Durch die Einführung von elektrischen Heizstäben im Schmelzbecken können Fabriken die Schmelzleistung erhöhen, ohne die Ofenabmessungen zu erweitern. Dies ist besonders nützlich für die Herstellung von hochreinem oder Spezialglas.

Industrielle Glasöfen helfen auch bei der Emissionskontrolle. Low-NOx-Brenner minimieren die Stickoxidbildung, während Sauerstoff-Brennstoff-Systeme Kohlenmonoxid- und Partikelemissionen reduzieren. Da sich die globalen Umweltgesetze verschärfen, wird diese Technologie immer wichtiger.

Branchen, die diese Öfen verwenden, profitieren von einer höheren Produktionsleistung, reduzierten Brennstoffausgaben und einer verbesserten Produktqualität. Zu den Anwendungen gehören Solarglas, Automobilwindschutzscheiben, Behälterflaschen, Architekturverglasung und Laborgeräte.

Letztendlich hat sich der Industrielle Glasofen zu einem hochentwickelten, energieeffizienten System entwickelt, das die moderne Glasproduktion im großen Maßstab unterstützt und gleichzeitig strenge Umweltstandards erfüllt.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!